- Email: montalbonoel@yahoo.com

- Hotline: 0945-2202-545

RETM MAINTENANCE ROPE ACCESS SERVICES

a multi-disciplined business offering services to the Oil and Gas, Petrochemical, Power, Water, Construction, and Facilities Management industries from our offices in the Philippines. Our extensive skill base of professional management from the Philippines enables us to understand client requirements and deliver a professional service with measurable results.

About Us

POWER AND PETROCHEMICAL

RENEWABLE ENERGY

BUILDING ENVIRONMENT

OFFSHORE OIL AND GAS

Vision

Mission

- To provide high-quality rope access services that ensure safety, efficiency, and cost-effectiveness.

- To uphold the highest standards of safety and environmental responsibility.

- To continuously invest in the training and development of our people.

- To build long-term partnerships with our clients based on trust and proven results.

Core Value

- Safety First – We prioritize safety in every task and decision.

- Integrity – We deliver services with honesty and accountability.

- Excellence – We strive for precision, innovation, and continuous improvement.

- Teamwork – We achieve more by working together with our clients and colleagues.

- Teamwork – We achieve more by working together with our clients and colleagues.

Our Services

- Rope Access Inspection & Maintenance

- Industrial & Structural Cleaning

- Cargo Hold Cleaning (Marine Industry)

- NDT & Ultrasonic Thickness Measurement

- Painting & Surface Preparation

- Installation of Cables, Pipelines, and Equipment

- Welding & Mechanical Works at Height

- Rescue & Safety Standby Services

- Customized Rope Access Solutions

- Local Rope Access Training

Industries We Serve

- Oil & Gas (Onshore & Offshore)

- Shipping & Marine

- Power Plants & Utilities

- Construction & Infrastructure

- Telecommunications

- Manufacturing & Industrial Facilities

- Blade Inspection and Composite Repair

- Confined Space Entry and Rescue

- PPE Inspection

Quality Statement

RETM MAINTENANCE ROPE ACCESS SERVICES

Recognizes that the disciplines of Quality, Health and Safety, and Environmental Management are integral to its management function. The Organization views these as a primary responsibility and to be the key to good business in adopting appropriate Quality standards.

The Organization’s Quality policy calls for continuous improvement in its Quality Management activities and business will be conducted according to the following principles:

- Comply with all applicable laws and regulations.

- Follow a concept of continuous improvement and make the best use of our management resources in all Quality matters.

- Communicate our Quality objectives and performance against these objectives throughout the company and to interested parties.

- Take due care to ensure that activities are safe for employees, associates subcontractors, and others who come into contact with our work.

- Work closely with our customers and suppliers to establish the highest quality standards.

- Adopt a forward-looking view on future business decisions, which may have an impact on Quality.

- Train our staff in the needs and responsibilities of Quality management.

Health, Safety, and Environment (HSE)

Safety is at the core of RETM operations. Our rope access system is built on redundancy, safe work procedures, and continuous monitoring. We conduct:

- Job Hazard Analysis (JHA) & Method Statements

- Emergency Rescue Planning for all projects

- Regular Equipment Inspections & Certification

- Ongoing Training & Safety Drills

- Provide adequate control of the health and safety risks arising from our work activities;

- Consult with our employees on matters affecting their health and safety;

- Provide and maintain safe plant and equipment;

- Ensure safe handling and use of substances;

- Provide information, instruction, and supervision for employees;

- Ensure all employees are competent to do their tasks and to give them adequate training;

- Prevent accidents and cases of work-related ill health;

- Maintain safe and healthy working conditions; and Review and revise this policy as necessary at regular intervals.

CLIENTS & PROJECTS

- Malampaya Offshore Platform - SWP

- JG Summit Petrochemical Corporation

- Three60 Energy FPSO / Rubicon Intrepid

- JG Summit Stage 1 Expansion Project

- Prime Energy

- MDC – Makati Development Corporation

- Vestas – Global Leader in Sustainable Energy

- MDBI – MDBI Construction Corporation

- Alveo Land Corporation

- Taal Volcano Area Rescue

- KFC Building Batangas City

- Pontefino Hotel and Residences

- Sampaguita Farm

What Is Rope Access System?

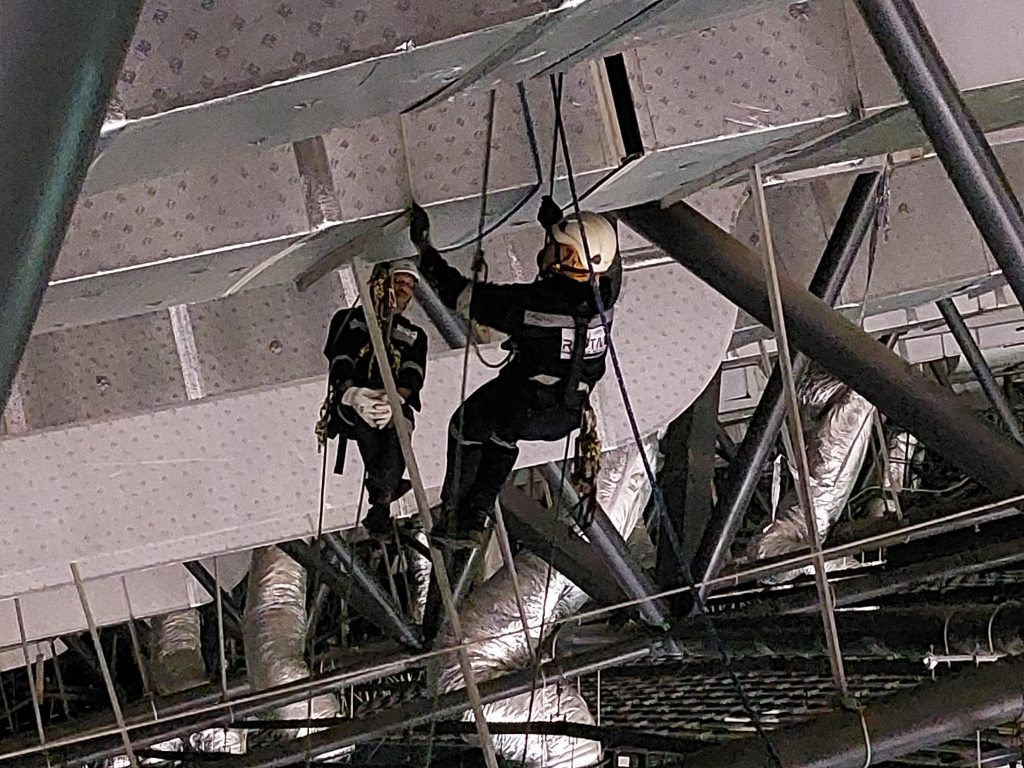

The primary purpose of rope access is to enable workers to access difficult-to-reach locations without scaffolding, cradles, or aerial platforms.

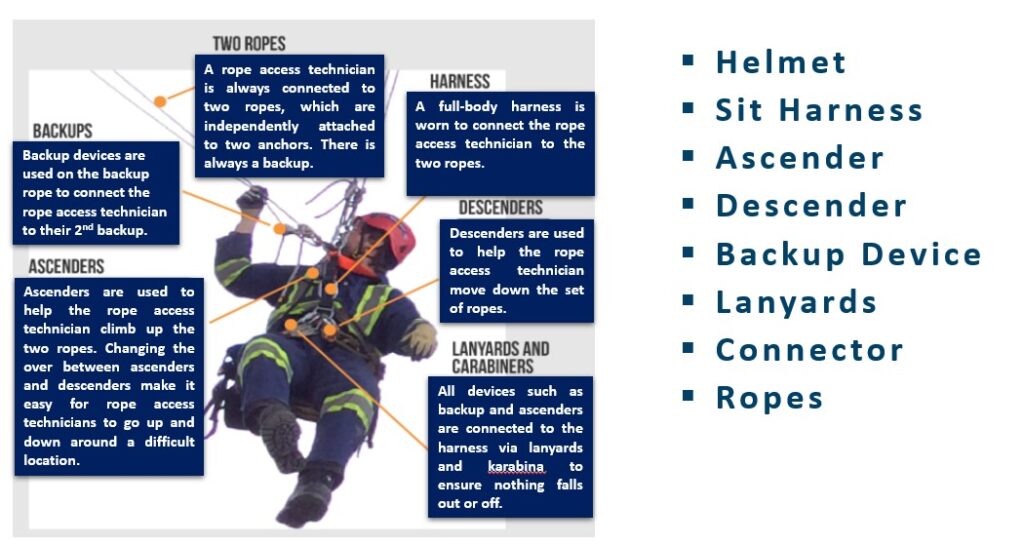

A rope access technician will use ropes to descend, ascend, or traverse while held in place by a harness, and sometimes a rope access work seat as well.

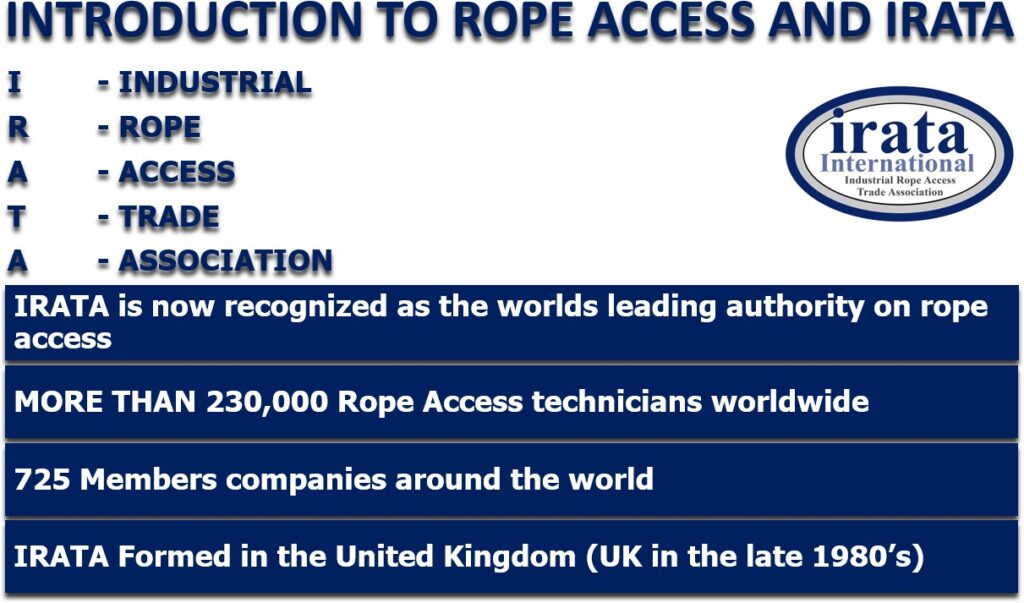

Rope access first came into use for industrial work in the 1980s. Since then, trade associations like IRATA (Industrial Rope Access Trade Association) and SPRAT (Society of Professional Rope Access Technicians) have codified it, turning it into a tested and reliable method for getting people into hard-to-reach places for work.

To satisfy rope access safety requirements, rope technicians commonly use several redundancies to ensure they’ll still be safe in case part of their equipment fails.

Two common redundancies are:

1. A backup fall arrest system, utilizing two ropes for redundancy—comprising a working rope and a safety rope.

2. Additional anchor points, including a primary anchor point and two backup anchor points.

- The main advantage of using rope access lies in the speed and safety with which they allow workers to reach hard-to-reach locations in order to perform their work, often with minimal impact on other operations and surrounding areas.

- Comparing the man-at-risk hours and associated risks and costs of access to such locations with other means of access, rope access generally reduces both the time workers are exposed to risk and the degree of that

List Of Fall Protection Equipment

Information Of Fall Protection Equipment Set-up

Our Rope Access Services

RETM MAINTENANCE ROPE ACCESS SERVICES Works in the Energy or Power Generation Industry for Repairs and Preventive Maintenance.

Our specialty in the Energy sector includes:

- Installation of safety catch nets.

- Application of protective coatings and lining materials.

- Non-destructive testing (NDT) and structural testing services to help determine the structural integrity of industrial chimneys, smokestacks, or other generating plant structures.

- Bolting and torquing.

- HP, UHP cleaning, and boiler washing.

- Work at Heights Rescue.

- Rigging services.

- Silos, tanks, vessels and cooling tower cleaning and Maintenance.

- Wind turbine Cleaning, Painting, and Blade Repair.

Our range of services includes:

- Lightning protection installation, repair and replacement on tall structures.

- Cable pulling and trunking Installation.

- Piping and jet lines on jack-up rigs.

- Sandblasting.

- Welding Installation.

- Sand and Grit blasting.

- Steel erection.

- Video and photographic surveys.

- Insulation removal and replacement.

- Beam and structural replacements throughout oil rig derrick structure, platform etc.

Other Rope Access Services

- Industrial painting including airless spray painting.

- Fiber optic installations and various lighting applications and installation.

- Mastic sealant application.

- Building cleaning.

- Field Water Test AAMA 501.2

- Installation maintenance.

- Panel, Glass and billboard replacement Installation.

- Erection and installation of protective screen and visor netting.

- Erection and maintenance of tensile fabric canopy structures.

- Removal and installation of vent lines.

- Aircraft warning light Installation.

- Glass Panel Installation.

- Fabrication maintenance.

- Window cleaning.

- Waterproofing.

- Banner frame erection.

- Panel washing/cleaning.

- Roofing repair and replacement

- PVC banner installation and removal.

- Vinal application and removal.

- Cladding Installation.

- Signage installation and replacement

- Blind installation, repair and removal.

- Gutter cleaning.

- Spray Painting.

- Sheeting replacement

- Safety Net Installation.

- Various electrical work.

- In-house Rope Access local training.

What is Rope Access Training

Industrial Abseiling Course Designed to Help Organizations and Operatives Meet the International Standards of Work Height Regulations via Rope Access System

We offer in-house Rope Access training courses at RETM MAINTENANCE ROPE ACCESS SERVICES, conducted in accordance with IRATA guidelines to ensure the highest quality training. This preparation equips trainees to handle various situations in the workplace effectively.

Local Rope Access courses cover levels 1, 2, and 3, ranging from basic training at level 1 to advanced competency at levels 2 and 3. These courses enable delegates to work safely at heights using diverse rope techniques, with levels 2 and 3 building on these foundational skills.

Our local Rope Access training on rigging, combined with an engineered anchor selection program, ensures flexibility while upholding the highest safety standards.

The training courses span a minimum of 30 hours over 4 days. Geared towards individuals unafraid of heights and aspiring to become Rope Access technicians, the course serves as preparation for assessment and qualification as IRATA-certified technicians capable of performing a specified range of rope access tasks.

Conducted by certified IRATA Rope Access Level 3 Trainee Instructor expert, Mr. Ed Atienza, with IRATA no.: 3/5140t. All IRATA-certified technicians receive a unique IRATA number during their initial assessment. This number, along with the technician’s surname, allows verification of their level and expiry date through the “Technician Check” feature on the IRATA website.

Rope Access Method vs Scaffolding

COST – EFFECTIVENESS

One of the most important things when it comes to any construction project is time. The more efficiently things are done on a site, the less time and money are wasted.

The construction of scaffolding, on all counts, is more costly. It requires specialized equipment that needs to be transported and constructed— which takes time. Deconstruction is also time-consuming, making it an unappealing option when you’re pressed to hit a deadline.

The time needed to set up rope access, on the other hand, is far shorter. Industrial rope access also needs significantly less equipment and is made up of far less costly materials. They are also less versatile, as scaffolds over a certain height often need special licenses in order to be constructed

ENHANCED SAFETY MEASURES

At first glance, rope access methods might seem more dangerous, but it has been seen that they are by far the safest option among all the means of high access.

This is because technicians are rigged to two separate ropes as a precautionary measure. One acts as the mainline, while the other acts as a fail-safe should the mainline fail. Tools are also tethered to technicians in case they are dropped, preventing injuries from falling tools.

Given their high standards of required training (more so than scaffolding or other types), rope access professionals exercise proper safety protocol and are injured far less often.

FLEXIBILITY

Depending on the architecture and design of a building, there are parts of it that will be difficult to access even with scaffolding. The wonderful thing about the rigging used to set up rope access is that it takes up very little space, and experienced technicians can reach these difficult spots with ease.

AESTHETICS / MINIMAL DISRUPTION

Rope access is also more friendly to the eyes, as the structure of a building is not covered up by unappealing scaffolding. It allows for repairs and maintenance to be performed without drawing too much attention to these operations. It also allows for minimal disruption of the building’s operations, and won’t block too many windows and doorways.

CONCLUSION

While scaffolding is highly unlikely to go away in construction, the option of industrial rope access should be considered for whatever repair, high- rise glazing, or maintenance projects your building may need to undertake. Not only is rope access cost-effective, but also space-saving, time-efficient, and safe.

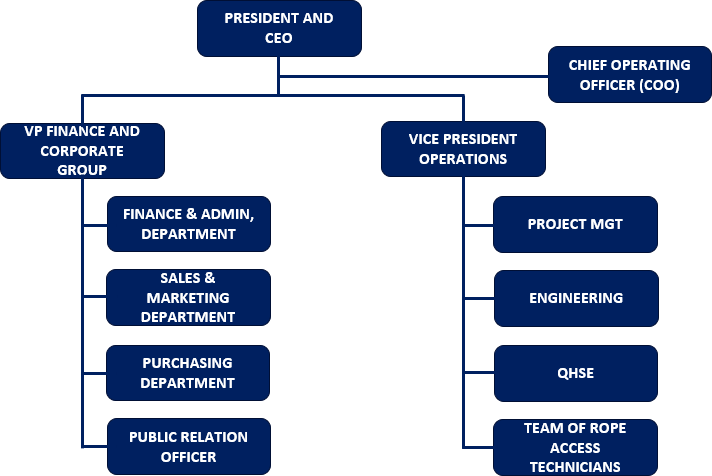

Organizational Chart

SUPPORT 24/7

Are you having a question, or want some help from us. Don’t hesitate, send us your request today

Contact Us

Sitio Gitna, San Isidro, Batangas City

Services

Installation of Insulation and Cladding

Welding

Window Cleaning

Water Proofing

High Pressure Wash Cleaning

Other Services